Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Fixing Locomotive Problems

Model locomotives are usually well made, durable, and give good service over a long life. Like any electro-mechanical item, they do have problems from time to time.

The first thing to look for is dirty wheels. For good running you need good electrical contact between the wheels and tract, so both should be clean. As the track gets dirty, the wheels pickup the dirt, and dirt causes poor contact between the wheels and the track. Use a brass brush to clean the wheels, not sandpaper or a file, as they would cause scratches on the wheels, which would just attract more dirt.

The next step in finding locomotive problems is observation. Watch it in operation, on straight track and curved. Does it jump or stall going through turnouts? Get down to track level and watch it slowly run by. Does it wobble, jerk, crab sideways? You won’t know what to fix until you know what the problem is.

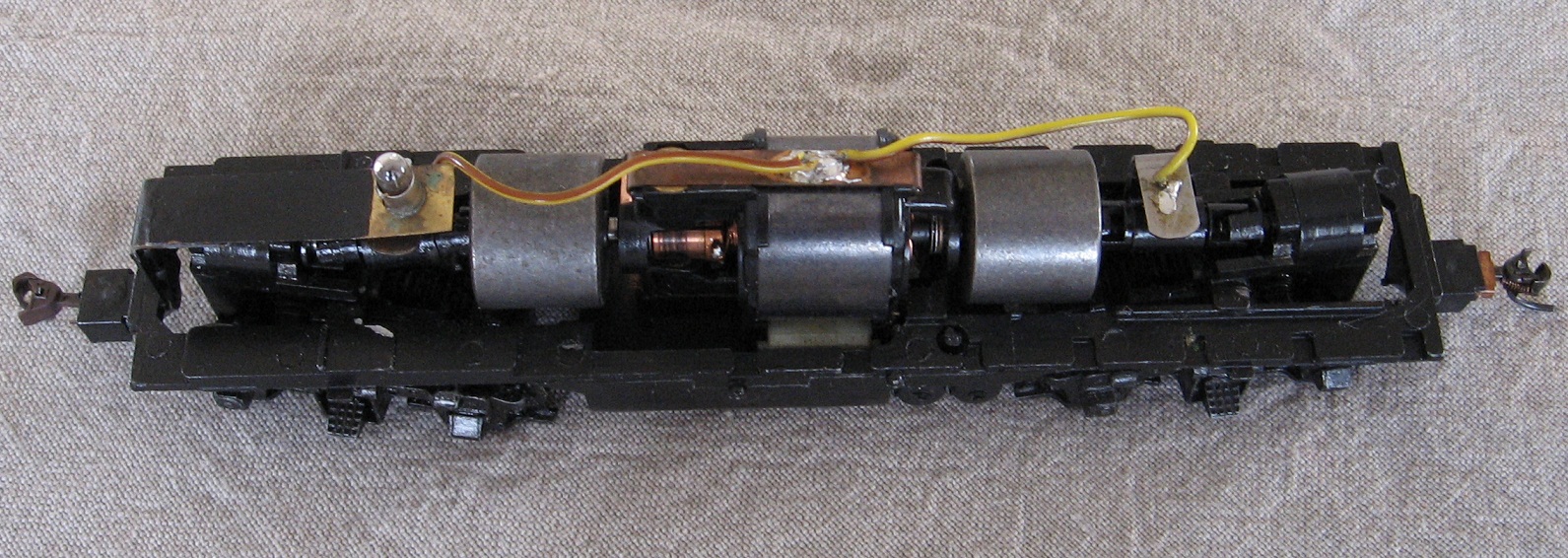

Before taking your locomotive apart, take a good look at how it is put together.

Take a digital picture of each step, so you will know what goes where, when the time comes to put it all together again.

Many screws and parts are very small, and easily lost if dropped on carpet. You might want to place an old bed sheet on the floor to aid in finding any items dropped.

Use a small cake pan to hold the parts and store the locomotive between work sessions.

Clean the individual parts with a lint free cloth, cotton swab fibers are bad. A lot of the screws in a model locomotive have very fine threads and go into soft metal or plastic parts. Use caution when tightening screws so you don’t strip the threads.

Add your comments

4 Responses to Fixing Locomotive Problems

Leave a Reply

At my work desk I have attached a piece of fabric, about 36″ L x 24″ W, under the edge of the table by means of Velcro tape. When I sit down to work on finicky stuff I draw this piece over my legs up to the waist and any part dropped will be caught right there. I recommend using plain fabric without any pattern. Very small pieces tend to hide in patterns.

The Velcro makes it easy to remove when not needed or when it needs to get thrown into the washing machine 🙂

Whenever I have small parts of a loco; or open a packet of screws or pins, I prefer to place all the bits and pieces in a clean plastic food storage container with a clear lid and snap locks . If one size is standardised, they can be labelled and stacked on a shelf or a bench. This type of container is also useful when a kit of any kind has been opened, although it may be necessary to have on hand a larger container.

I use small white plastic food container trays about an inch deep that we can buy at our local supermarket. I use white ones as it is easier to see the small parts. On the underside of one I have glued on a piece of sheet magnet like some fridge magnets use, this holds small metal screws in the base of the dish and if it happens to get bumped the parts stay in the dish.

I run a lot of Athearn locomotives and if you find that your locomotive is starting to run slower and/or needing a higher starting voltage(or higher throttle input) go to the dollar store and buy a package of wood pencils, remove the body, set your loco on a block so you can run it while it’s stationary(a track cleaning block works great) and hook jumper wires to it, now turn the throttle way up! take the pink eraser and gently clean the motor’s contacts till they are nice and clean.