Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

29 Smart Ways to Prevent Model Train Derailments (Part 2)

Trackwork, Weighting, and Setup Tips for Smooth, Reliable Model Railroad Operation

If derailments are still sneaking up on your model railroad, don’t worry… you’re not alone. Even well-built layouts can suffer from annoying tip-offs and wheel lifts if a few key details are overlooked. The good news is that most derailments are caused by small, fixable issues, especially around car weight, track alignment, and transitions.

In Part 1, we covered maintenance basics like wheel gauge, couplers, and cleanliness. In this second installment, we’ll focus on trackwork and rolling stock setup, which play a huge role in keeping your HO, OO, or N scale trains running smoothly.

Below are Tips 13–23 in the complete series of 29 derailment-prevention techniques. (The final tips continue in Part 3.)

Why Weight and Track Quality Matter So Much

Model trains are light by nature, which means they’re far less forgiving than the real thing. Slight bumps, uneven joins, or poorly balanced cars can easily push wheels off the rails. Getting the fundamentals right here will dramatically improve reliability across your entire layout.

Tips 13–23: Preventing Derailments with Better Weight and Trackwork

13. Weigh Your Cars to a Consistent Standard

Rolling stock that’s too light tends to wobble, bounce, or derail… especially through turnouts and curves. Use NMRA (or local equivalent) recommended weights as a guideline to keep cars stable and predictable.

14. Add Extra Weight Where Needed

If a car feels “floaty” or tips easily when handled, it probably needs more weight. Extra mass helps wheels stay planted on the rails and improves tracking through curves and minor imperfections.

15. Keep Added Weight Low and Centered

Where you place the weight matters just as much as how much you add. Position it as low and central as possible to lower the center of gravity. This reduces rocking and side-to-side sway, especially on curves.

16. Balance Weight Evenly

Uneven weight distribution can cause a car to lean, overload one wheelset, and increase derailment risk. Try to balance weight left-to-right and front-to-back so the car rides flat and true.

17. Watch for Wheel Lift on Tight Curves

Sharp curves are a common trouble spot, particularly for long cars or lightweight rolling stock. If wheels lift or cars lean excessively, your curve radius may be too tight. Added weight can help, but redesigning the curve or using shorter cars may be the better solution.

18. Inspect Every Track Joint

Even a tiny misalignment at rail joins can grab a wheel flange. Run your fingertip across joints… if you can feel a bump, your trains will feel it too. Light sanding or filing can eliminate many hidden derailment causes.

19. Make Sure Track Is Level

Baseboards and benchwork aren’t always perfectly flat, and small dips or humps can throw cars off balance. Use a small spirit level and check trouble spots regularly, especially near joints and turnouts.

20. Keep Rail Gaps Minimal and Consistent

Oversized gaps between rails can cause wheels to drop, particularly in smaller scales like N. Keep gaps tight and uniform while still allowing for temperature expansion. Alignment is just as important as gap size.

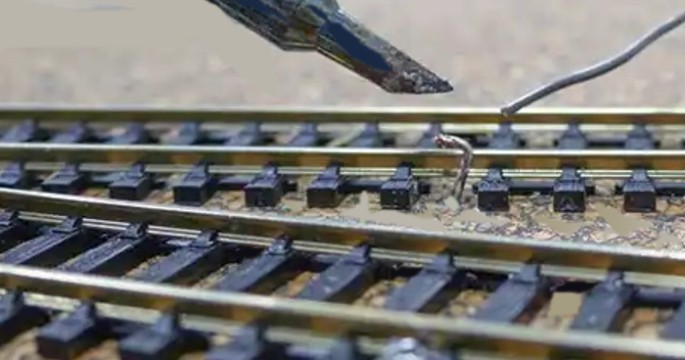

21. Solder Track Joins for Stability

Soldered rail joints are far less likely to shift over time. Unsoldered joins can slowly open up due to temperature changes or layout movement, leading to electrical issues and derailments. Soldering improves both mechanical strength and electrical reliability.

22. Smooth Rough Edges and Excess Solder

After soldering, inspect the rail carefully. Any bumps, blobs, or sharp edges can snag wheel flanges or coupler trip pins. A fine file can quickly smooth these areas… just be careful not to scratch the railhead.

23. Ensure Smooth Transitions Between Track Sections

Sudden changes in direction or height… such as from straight to curve or one baseboard to another… are derailment magnets. Transitions should be gradual and flowing. Always test with rolling stock before ballasting or final wiring.

Test Early, Fix Easily

One of the best habits you can develop is testing constantly. Roll cars by hand, push long trains slowly through problem areas, and watch closely for wobble or hesitation. It’s far easier to fix issues before scenery and ballast lock everything in place.

Coming Up: Part 3

The final part of this series will cover advanced derailment prevention tips, including turnout tuning, grades, train length, and operational practices that keep trains running reliably during long sessions.

Final Thoughts

Smooth-running model trains don’t happen by accident. They’re the result of careful weighting, solid trackwork, and attention to small details that many hobbyists overlook. Dial these in, and you’ll spend far less time rerailing cars—and far more time enjoying realistic, frustration-free operation.

Your trains deserve it.