Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Family Work On Model RR Project

A few weeks ago Tim sent in some info about the model train layout he is building with the help of his wife, uncle and nephew. He has now sent in some more details he would like to share with others in the hobby. He aslo gives some tips based on his experiences working on the RR project:

A combination of things then slowed my progress. My nephew came over two weekends after finishing the construction of the table and we began laying track on the table. I own several Accurail 89 ‘ foot car carriers so I wanted curves that could accommodate them.

Some days later, I took my wife out to dinner and after wards we headed to Lowes. I immediately searched for a dry wall saw and bought one along with several other tools.

Lessons learned and equipment being used:

I am principally modeling the Missouri Pacific though I have engines from the Southern Railway, Rock Island, and Illinois Central. I am attempting to model from the early seventies to the early nineteen eighties. I am loosely basing my layout on the old CE&I line bought out by Missouri Pacific in 1967. I initially wanted to have a small town with a single farm and a grain elevator for the industry, but I quickly learned that I didn’t have enough room on my 4X8 table.

I immediately simplified it to a couple farms and the grain elevator. In order to add some variety, I placed a river to the west end of the table and a highway overpass to cross a road over the mainline and servicing siding for the grain elevator.

The Highway Overpass

As part of my rr layout, I am building a highway overpass to cross a country highway over the main line and the spur lines at the elevator. The kit that I am using is a Rix Modern Overpass kit. It comes in 50′ foot road sections (measure 7 inches long) and the piers.

I started by painting the pieces; however, this turned out to be a bad idea. I primed them with gray primer spray paint and I then painted them with concrete gray. This creates a couple major problems. First, it makes it difficult to glue the pieces together.

Each foundation consists of holes where piers go. The holes helps hold the tubes in place plus they permit you to adjust the height of the bridge. Painted even with just the primer causes the holes to be almost too small for inserting them. You will most likely tear up the tubes or the pieces that you are inserting them into.

Once I got my first hill up, I realized that my pier was too high (full height is 6 inches). I tried cutting it down, but that caused the plastic to tear. I then had to start over.

Recommendation

Measure the height of the area to be crossed to determine the height for your piers prior to building them (if you need taller piers the company recommends that you use Plastruct tubing).

I also recommend measuring the distance you intend to cross so you can glue the appropriate number of road sections together. This permits you to line up your “I” beams and glue it more securely. Use a strong glue like a gap glue for assembling them due to the weight.

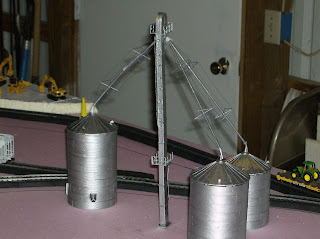

The Grain Elevator

This is also a Rix kit. As stated earlier, I found gluing this together to be difficult. Just before Thanksgiving, I traveled to a new hobby store in Marion, IL called “Chuck’s Depot.” The owner suggested that I use a glue made by Faller called “Expert: Plastic cement” for working with the Rix products. This glue worked adequately to build the conveyor leg shown below.

You must buy the conveyor leg and its bins separately. Technically, it comes with plenty of parts between the grain bin and the leg, but if you make some mistakes or lose some parts you’ll come up short quickly.

Rix’s produces an expansion kit and another that provides extra parts for the bins; however, they don’t yet provide any for the conveyor leg. It requires two auger pipes to connect the leg to a 44′ foot grain bin. Each tube provided is 5 inches long so I cut one inch from each pipe to make them eight inches. I found the Faller’s glue not strong enough for the auger pipes. I recommend a gap glue for those. I put the augers on last and this created all kinds of problems.

In building a second conveyor leg, I glued the parts that hold the pipes in place to the “head” prior to assembling anything else. It allows you to hold pressure to insure adequate bonding without damaging the details on the leg.

I am also planning to use Evergreen styrene tubes for the augers instead of the tubes provided (more on that in a later article). Use a strong glue due to the weight of holding the pipes up (I used Gap glue). I also used Gap glue to glue the platforms together. Don’t wait for the platforms to dry before assembling to the leg. They must be flexible enough to wrap around the leg. I used the gap glue to glue the cage that goes around the ladder. You may use any glue for putting the sections of the leg up. For support wires, I used regular thread, I found the support wires provided with the kit too flimsy. I tried 15 pound test fishing line. This has too much torque and it wants to pull away from the glue and bends the augers.

To submit details of your layout for publication go to http://www.model-railroad-resources.com/my-layout.html