Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Improvements to Basic Layout

Lucky is just getting started in the hobby and seeks advice from others who have progressed to a more advanced level. Here is his question:

“I am new to modern age of model trains. I set up a basic set for grand kids. It is very “Mickey mouse”, so I would like to move up to reasonably priced set with latest features. Maybe still retaining the style of loco and cars young children would enjoy, but with an improved power supply. The Lionel booklet suggests an 80 watt transformer cw80. I assume I will need connection to track? Any help would be appreciated.”

Track Modification Suggestions?

Daniel asks:

“I am trying to run two lines into a O scale Lionel Train Station Co. I guess out of a switch, I can’t get one of the lines in parallel with the other one. How do I modify track to make the curve coming out of the switch? Can the track be adjusted by loosening the metal ties?”

Which Track Type or Brand is Best?

Reg S posted this question to the Blog Moderator by using one of the ASK A QUESTION links on this Blog:

“After buying a Bachmann train set for one of my grandkids I decided to have a go myself and construct a simple layout in HO scale. After looking around online I see there are multiple choices. Although the E-Z Track type looks easy and foolproof,…maybe what I need… ha ha… it doesn’t look so real or flexible enough if I want to make changes later??? Also, I read that Bachmann is not all it’s cracked up to be??? I know it is priced cheap so maybe you get what you pay for???

I would like to hear from the old hands at this on what is the best type or brand of track for me considering my layout will be fairly basic. Thank you to everyone.”

If you would like to comment on this question from Reg, or provide an answer, all you do is add your comment under this post. All comments go to the Blog Moderator and, unless they contain spam or don’t make sense, will be published usually within a few minutes depending on the time of the day.

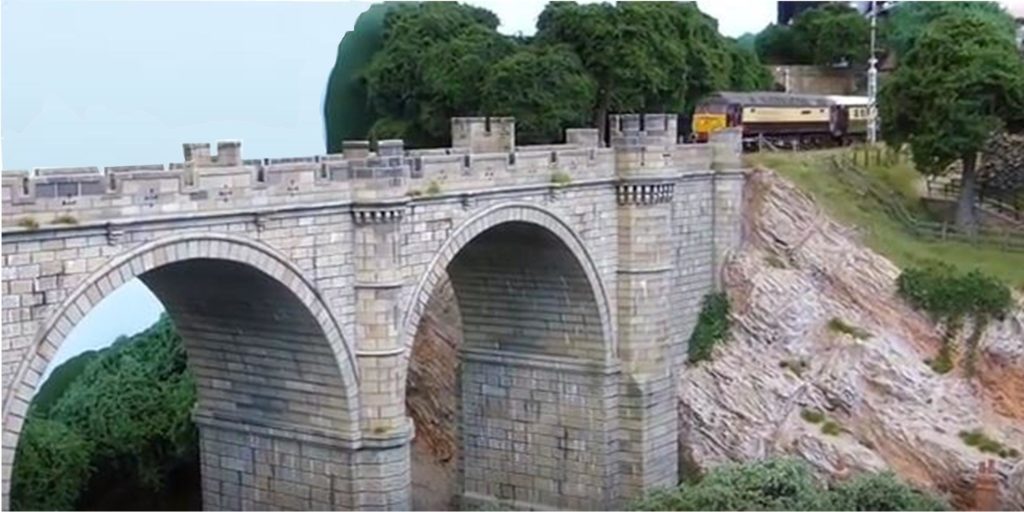

Impressive Arched Bridge on Display at the York Model Railway Exhibition

Online Model Train Club Member Frank R W sent in these photos he snapped at the York Model Railway Show in the UK a couple of years ago.

Obviously a substantial structure like this a very expensive and time consuming to build. It is certainly impressive and it you have the space and resources it would be a great project to work on. If you are not in that position then there are cheaper and easier options here.

Adding Hidden Pulling Power To A Train

Purna asks readers the following:

“Can I make my HO scale train more powerful by adding more locos which are “hidden” in the skin of carriages? Will it be effective? And can all such locos be synchronized well (without derailing etc.) Is DCC good for that? My real objective is to make a GHAN train with two visible locos (even though the rest of the powering locos are hidden) with a number of carriages about 50 in my model layout… Have any of you tried doing this? Will the power of the train drop if the track is too steep or with lot of bends”

The Ghan’s 2,979km (1850 mile) journey takes 48 hours and has been operating from the through central Australia since 1878. The train runs from the far south up through the middle of Australia to the far north. The Ghan was originally called the Afghan Express. The Ghan name is from 19th century Afghan camel drivers who ventured to Australia to help to explore the country’s remote largely arid interior.

Getting Atlas Switch Tracks to Operate Properly

Paul posted this question:

“I am having trouble getting my N scale Atlas switch tracks to work. I have tried all different wiring configurations. They will throw in one direction and when I try the other direction, all I get is a hum from the switching machine mounted on the track. The hum tells me they are getting current but nothing happens. If it were only one track, I would chalk it up to a defect in that track, but it is all of them (8). Very frustrating. Hope you can help. Thanks.”

Contribute your comment, photo, diagram using the COMMENTS tag directly under Paul’s post.

Reverse Loop Shorting Out

HO enthusiast David G asks readers this:

“I’m DCC – an NCE 5 amp. Am attempting to wire MRC auto reverse module. Loop returns back to main track thru set of points but shorts when points are set to left. Have isolated insulfrog point ends still same prob. One engine has enough weight to run thru without derailing when points straight ahead without derailing. Hookup cars won’t do same.”

You can submit your question to the Blog Moderator for publishing by clicking one of the several ASK A QUESTION links on this blog.

Making Fuel Tanks For A Model Train Layout

Garry W, a member of the Online Model Train Club from Caboolture near Brisbane in Australia, snapped this photo at a local model railway exhibition. Garry queried how these fuel tanks were made. He thought they looked scratch built from recycled plastic containers, and would like to hear what others think. Gary pointed out, “They certainly add interest set alongside the track, but I did wonder if they were too close to moving (potentially derailing) trains?”

If you have any thoughts on making fuel tanks or have a photo to share, just submit your contribution using the COMMENTS link under this posting. You will also be able to see what others sent in.

Ideas for Desert Scene Wanted

Morgan is looking for ideas and inspiration from experienced railroaders:

“I am planning a totally false HO model rr. It is the PRR in west TX. Now, the layout is shelf, and minimal scenery. But, has anyone experience with modeling the desert/mountain area of west TX? What is the best ballast to use? What colors of paint should I buy and where can I get pictures of the tracks out there? I live near DFW and can’t get to the west. Don’t drive anymore, etc. Best of all would be pictures of your model rr with that type of scenery. Thanks.”

Readers can add a comment and/or upload a photo using the COMMENTS link under Morgan’s post.

Ideas for Making Water Tower Ladder

David puts this question:

“I made a water tower on my HO set . I want to make a ladder for the tower. Does anyone have any suggestions please?”

HO Track Separation

Online Model Train Club Member Ben submitted this query:

“I have limited space so want my opposing tracks close enough not to waste space, but far enough apart not to cause collisions or look fake. How far apart should I make them?”

Add your comments (or view all comments) using the COMMENTS link. Submit a question using the ASK A QUESTION link. Easy!

Nightmare Wiring Switches

A question for readers from Phillip in Chatswood, Sydney, Australia:

“My single track layout will be laid out over 2m by 3m. I’ve never wired switches but read up about it a bit and want to know the pitfalls to avoid in advance. Much appreciated for letting me post this.”

Submit your question to the Blog Moderator for publication by using one of the ASK A QUESTION links on this blog.

Walthers Cornerstone Motorized 130′ Turntable Not Working

Wolfgang posted this question:

Wolfgang posted this question:

“Hello Friends, this afternoon my N scale Walthers cornerstone turntable stopped working. Instead of Power Control LED shows ‘on’ the bridge doesn’t work. What can I do? Thanks for any helpful ideas. I am living in Germany and maintenance by a hobby shop is not easy to get.”

Post your question to the Blog Moderator by using one of the many ASK A QUESTION links on this page.

What’s the Loco Number Limit in DCC Zones?

Geoff has this question:

“I’m new to DCC. I’m planning a small UK OO narrow gauge layout. The system I bought has an output of 2 amps. The circuit protector can have up to six zones, but 1 amp each. The docs say that the 2 amps will power up to 4 HO locomotives at one time, but am I right in thinking that the circuit protector will limit that to 2 in each zone? The docs for the circuit protector say you can connect it in such a way to have 3 zones 2 amps each, which perhaps is what I need to do?”

How Would a Dentist Fill The Gaps Between Tracks?

Online Train Club member Joshua is not a Dentist but asks:

“I know when I go to the dentist he tells be to floss between the gaps in my teeth. He doesn’t seem to want to close the gaps, whereas on my railroad that’s precisely what I want to do. I want to leave tiny gaps 1/32th between track to allow for movement, but I have 4 gaps closer to 1/16th. How can I fill these or should I make an appointment with my Dentist? Ha! Ha!”

Track Parts to Identify

Pradyot hasn’t supplied much information, but has obviously seen this track part on the net:

Pradyot hasn’t supplied much information, but has obviously seen this track part on the net:

“Please identify the item. What’s the use of it? Can it be placed on my N scale D.C. layout? Thanks.”

Keeping Track of Small Parts

Online Model Train Club member Erik shared this suggestion:

“I know some folk in the hobby use masking tape to hold small screws and parts to stop them rolling under the layout and getting lost. It is a very good idea, but I have another option to add to that.

My local hardware store sells small 5″ bowls with a magnet attached. One of these bowl is ideal for holding small steel parts.”

Auto Reverse Module – Digitrax and MRC Cab Controller Compatibility

William posted this question to readers:

“I have On30 and M.E. track and turnouts and DCC Cab Controller. I would like to install an automated reverse loop (does not to be that big as I will be running Porters with a few mining cars.)

I am electronically “challenged” and could use advice on what all I would need to set it up. I am in the planning stage now but I would like to know how to wire the turnout and loop section up front to see how feasible my idea is to have trains running on a continual basis in and out of the loop without needing to be manually operated. Is a module AR1 or the like all that is needed or do I need some type of ‘block’ detection? And are Digitrax and MRC cab controllers compatible as far as these loop modules concerned?”