Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

29 Proven Ways to Stop Model Train Derailments (Part 3): Track Laying Secrets for Smooth Operation

Want smoother running model trains and fewer frustrating derailments?

It all comes down to one thing: your trackwork.

In Part 3 of this derailment prevention series, we’re focusing on the final six track laying tips that can make or break your model railroad layout. If you’ve already worked through Tips 1–23 (covered in Parts 1 and 2), you’ll know that preventing model train derailments is mostly about careful planning, correct weighting, and solid maintenance.

Now it’s time to fine-tune your build.

Because once the baseboards are down and the track plan is decided, the real reliability comes from how well you actually lay that track.

Why Proper Track Laying Prevents Derailments

Many model railroad derailments aren’t caused by faulty locomotives or bad rolling stock. They’re caused by:

- Poor curve transitions

- Inconsistent radii

- Uneven joins

- Track movement over time

- Grades that are too steep

The good news? Every one of these problems is preventable.

Let’s dive into the final six derailment prevention tips that will help keep your trains running smoothly for years.

24. Test New Track Before You Commit

Before you wire it.

Before you ballast it.

Before you glue anything permanently.

Run trains over it.

Push a few freight cars and a locomotive slowly through every section of new track. Watch closely:

- Do the wheels glide through turnouts?

- Is there any rocking or wheel lift?

- Do couplers stay aligned?

- Does the loco hesitate or stall?

Small bumps become big problems later. Fix them now while access is easy. It’s much simpler to adjust bare track than to rip up ballasted sections.

25. Keep Your Curve Radii Consistent

Inconsistent curves are a hidden cause of model train derailments.

If a train enters a gentle curve and suddenly tightens into a sharper radius, the stress shifts instantly. Longer cars and locomotives are especially vulnerable to this change.

For smoother model railroad operation:

- Use the largest radius your space allows

- Keep radii consistent throughout the layout

- Avoid sudden “snap” transitions

Smooth, flowing curves not only reduce derailments — they also look far more realistic when a long train snakes through them.

26. Secure Track Firmly to the Roadbed

Loose track equals unreliable operation.

Over time, temperature changes, humidity, and vibration can cause track to shift slightly. Even a millimetre of movement can create:

- Alignment issues

- Kinks

- Electrical interruptions

- Wheel flange strikes

Secure your track properly using:

- Track pins

- Adhesive

- Foam-safe glue

Pay extra attention to curves and turnouts, as these areas experience more lateral force from passing trains.

Stable track is dependable track.

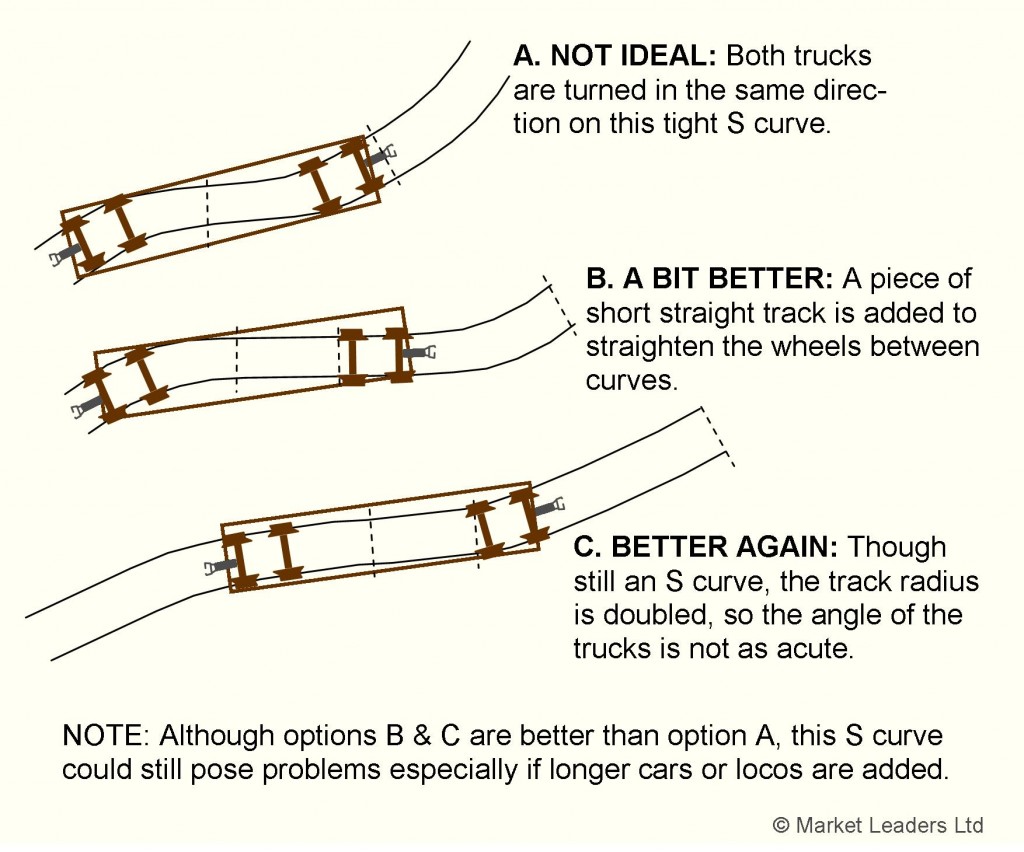

27. Eliminate Problematic S-Curves

S-curves (back-to-back opposing curves) are notorious derailment spots.

When cars are pulled in opposite directions without a straight section between curves, couplers are forced sideways. This creates tension that can easily lift wheels off the rails.

The fix is simple:

Always insert a short straight section between opposing curves.

Even a small straight buffer allows couplers and car bodies to realign naturally. That small adjustment dramatically improves reliability — especially for longer rolling stock.

28. Keep Grades Gentle and Manageable

Grades add visual interest and operational challenge. But steep grades are a major cause of:

- Stalling locomotives

- Wheel slip

- Runaway descents

- Derailments on curves

As a general rule, aim for a maximum 2% grade (roughly 2 inches of rise over 100 inches of track).

If space is limited:

- Extend the ramp length

- Use gradual vertical transitions

- Consider spiral climbs or wider curves

Gentle elevation changes keep trains stable and reduce stress on couplers and wheelsets.

29. Slow Down and Build It Right

Excitement is part of the hobby.

But rushing track laying almost always leads to:

- Tiny kinks

- Rail gaps

- Uneven joints

- Misaligned turnouts

And those small imperfections are exactly what cause derailments later.

Taking your time now saves hours of troubleshooting in the future.

Careful track laying isn’t the flashiest part of model railroading… but it’s the most important.

Final Thoughts: Reliable Trackwork Is the Foundation of Every Great Layout

If you want fewer derailments on your model train layout, focus on your trackwork.

Every:

- Curve

- Join

- Transition

- Grade

- Turnout

Matters more than you think.

Reliable operation isn’t about luck. It’s about preparation, precision, and patience.

When your track is laid carefully and tested properly, your locomotives glide smoothly, your rolling stock stays planted, and your operating sessions become far more enjoyable.

And that’s what this hobby is really about… watching your trains run flawlessly on a layout you built with care.