Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Peco Electro Frog turnouts With Circuitron SMAIL Switch Machines

Kim writes:

“I am working with Peco Electro Frog turnouts and I am using the Circuitron SMAIL switch machines but the electrical puzzle I am dealing with now has nothing to do with the motors. So this person from Iron Planet Hobbies says do not modify these so the jumpers underside are connected, There were connected out of the package and there is a frog wire. So in my photos I am showing first a single left turnout, currently directing the train to the curve so in that position switch is working fine. The other way I have set up as a switch throw and it goes into a spur by an elevator so what is happening, when I throw the switch and the blades move to other rails, it is causing a track fault.

So other photo is a crossover using two left turnouts. It is fine when they are in close (straight) but like the other one (#3), soon as I throw and blades contact other rails, FAULT. These switches are 2 A and B, I throw 1 A and B which is for a side and it does not fault. Other photos is a diagram and the underside showing the jumper.

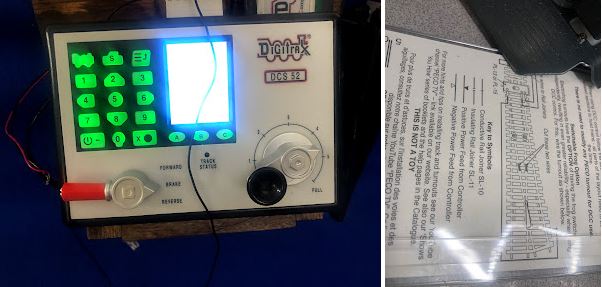

I live in mpls/St Paul MN and wished a had an electrical expert here. Motors are working great, moving switches very nicely. I started in front to get this working right before going to the back to the same switch layout but without the single switch. In the link, there is a photo of my Digitrax Zephyr DCS52. If anyone out there are using these same type switches, I could use some advice cause I am not understanding this.”

4 Responses to Peco Electro Frog turnouts With Circuitron SMAIL Switch Machines

Leave a Reply

If I am understanding your problem correctly, you need insulated track joiners where the two left turnouts meet.

I agree with Adam you need insulated rail joiners. but if you are using DCC, and if your point motors are facing each other you need to make sure that your live and common rails are not crossed, i ran in to this on my layout in the beginning.

I am having good luck with my peco turnouts after I learned the right way to hook them up. Now I also learned from experience with those that within the zones where the insulated joiners are, I needed to put track power feeds in cause those joiners stopped the flow of current so after I did all that it all worked great. I am having great experience with those (SMAIL) switch machines. I really like them. Now I have been going through the new track I put on and correct the joints and bumps. Oh I also experienced that the divider in those joiners keeps the ends of rails from coming together completely and leaves a gap(bump) Anything I can put in those gaps so there isn’t that bump that isn’t metlalic? curves are the hardest places to get joints to work right and it really tests patience. I use the alignment gauges too. Two of my locomotives are longer wheel base with 3 axle trucks like my GE ES44C4 and SD70ACe. If there are any imperfections in the joints, those locomotives will let me know about it. I really like my Digitrax DT500D wireless handheld to allow me to work on areas of layout without being by the Zephyr.(DCS52).

I agree with Adam and Andrew, insulated joiners are the go. I used the insulated joiners on both exit rails and put in a jumper lead on both rails after the exit rails. I have a five turnouts I ne behind the other creating five spur lines. The trains exit the other end. I use small micro motors. I run dc.