Troubleshooting

Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Club member Trevor asks readers for advice with his LED lights:

“Recently I installed lighting inside a couple of passenger train cars using the new led strip system. It worked perfectly until the train started to move and then the LED’s started to flicker which ruined the effect. I have a DCC system, and my track is clean. I have new wheels and pickups so I’m not sure what the problem is. I would appreciate any guidance from others who have experience using LED’s on their trains. Thanks in advance.”

Please add your comment if you think you can help Trevor.

You can join the model train club here.

Colin wants to hear from anyone who has relocated house and layout. He asks:

I made a big mistake not building my 11ft x 8ft HO layout in modules, although part is built on an 8 x 4 base and the rest tacked on.

Now we are moving interstate and I am not sure how to dismantle and move my precious railroad without damaging it. Most of the scenery is made from paper mache. The buildings and two bridges will detach okay. I can dismantle the legs without too much difficulty as they are screwed in place.

But, for the main layout itself, I don’t know where to begin. I don’t want to wreck it pulling it part or damage it in the move. I know I am probably asking the impossible, but I don’t know where to start.

Please help.

Although it is almost impossible to avoid all derailments, there are ways to limit the likelihood of them happening. This video has makes some excellent points.

The resource mentioned in the video

Colin asks readers:

“I’ve purchased an HO loco fitted with a DCC chip, and it operates great on DCC, however I can’t get it to move on DC. How can I

fix this?

If you want to submit a question to the Blog Moderator for possible publication, please use the link in the right hand column of this bog.

Jim asks readers:

“I have a Lionel Santa Fe freight train O scale (8689) with whistle and smoker. The train sat idle for much of the spring, but now that my son has gotten back to using it, the smoke stack no longer seems to work. Does anyone have experience with this? Could it be the fluid that was in the loco before he stopped using it glopped up while sitting idle? Or is it more likely an issue with what I presume is a tiny motor that pumps the fluid out? I’d like advice on how I could fix this, if anyone has any suggestions. Thank you.”

Add your comment to help Jim.

If you have a question you would like published you can submit it to the blog moderator for consideration. The link is in the right hand column.

Gene asks readers for advice:

“I have 9 HO scale locos (steam & diesel), that I have purchased over time. How can I tell if a loco I bought (don’t have the boxes anymore) is DC, DCC-Ready, or DCC inclusive? I can’t find markings on the locos themselves.”

Add your comment.

Shaun asks readers:

“I operate N scale trains. Is the weighting scale 1/2 ounce and then 1/4 per inch?”

And Shaun also wants to know where he can purchase American bogies or wheel sets.

Although a couple of these questions provide few details, hopefully a reader might be able to assist.

1. John asks readers:

OO Scale Tender Keeps On Spining

Why does my tender keep on spining? It is tender driven and sometimes it runs okay, then it stops then spins like mad. Is it the cogs? It’s brand new. Any ideas?

2. James asks:

HO Bachmann DCC Control

“I turn on the power and I get blinking red lights, but the engine will not run. I checked my wiring and can’t locate a problem. What would be the cause?”

3. Bernie asks readers:

L-Girder Tables – N Scale

“Does somebody out there know where I can get a diagram of how to cut a 4×8 3/8 plywood to make a table as well as directions on how to assemble and a part list of bolts nuts washers screws glue height adjusters?”

4. Denny asks readers:

Airport Ideas

“I want to add a local airport to my HO layout. Where can I buy 1:100 scale single engine aircraft?”

5. Jean asks readers:

Derailment at Point on Curve

I have a point at the beginning of a curve and the OO engine derails at this point every time – any suggestions – unfortunately I have had the pints wired up and are fixtures. Help please?”

Add your comments.

Andy asks readers:

“Do anyone offer help in converting an HO DCC equipped locomotive to Ring Engineering’s Rail Pro LM module installation?”

Add your thoughts.

Warren seeks guidance for others in the hobby and asks:

“Does anyone make HO roadbed to fit Bachmann easy track? We have alot of eztrack which I want to use instead of purchasing new track. Is it necessary to use roadbed under the eztrack or can I elimanate this step. I did plan on using ballast just not sure about the roadbed. ”

Add your suggestions for Warren.

Ron asks readers:

“To put sound in an N scale boxcar I’m told I need a 50′ box with metal wells and a truck with a metal frame for the electrical pickup. Where might I find such a thing or what should I ask for?”

Add your comment to assist Ron.

Donald has an N scale question for readers:

“How do I break open the N scale freight and passenger cars to add weight and what is best to use for that extra weight, hopefully keeping them on the tracks?”

Add your suggestion.

Jim wants to hear what other think:

“I recently bought a new Porter Hustler engine by Model Power on ebay. When I put it on the track it ran in the opposite direction of all my other engines. It is a problem on my layout. Any suggestions.”

Add you comments to help Jim.

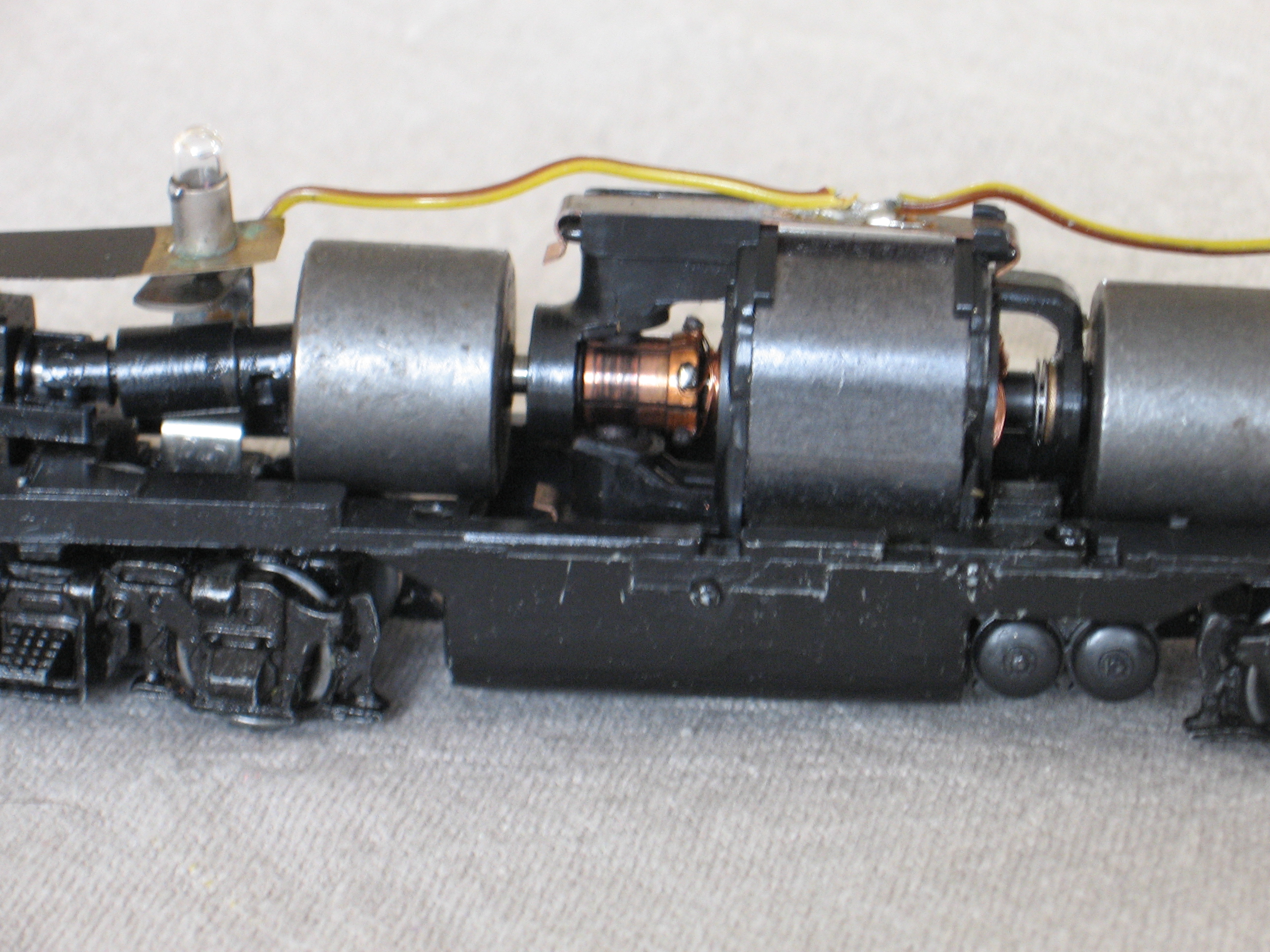

John asks readers:

“How do I dismantle an HO engine to find out why it makes a grinding noise but does not move on the track. I cannot figure out how to remove the engine cover/body. Thanks in advance, John.

Add your answer to help John.

Club member Angelo sent in these tips to share:

Anything with moving parts can experience problems from time to time, and locomotives are no different. To ensure smooth reliable running they need some care and attention. Here are 4 common problems and common causes:

Here are some more things to check:

Watch and observe (keep a record) of how the engine operates in both directions and at different speeds. Listen carefully to the engine sound (noise). You might discover the loco runs better in one direction and no so well in the other direction. It may also be noisier in one direction than the other. Also, check for any slack around the thrust washers. The wheel treads should be clean.

The wheelsets might have a coating that won’t conduct electricity. One option is to put the wheelset into an expandable truck frame and then burnish the wheels using a brass brush attached to a Dremel motor tool. You might already use a rotary brass brush for cleaning solder from your nickel silver frogs so this is another use. You can also buy packs of 3 brass brushes (they look a bit like toothbrushes) from Discount Stores for about $5. A Dremel brush can be used when the engine is running while resting on its back. Those with DC could use a Kadee wire brush. Alcohol (70% isopropyl alcohol) is an effective cleaner.

If you notice the locomotive movement is somewhat “jerky”, it could be caused by a tight part or by poor electrical contact. A diesel engine might not have enough play in the drive train, or if it’s a steam engine it might have binding in the siderods.

Also inspect the wipers. On some locomotives you’ll need to check the seating between trucks and chassis. Electrical pickup will rely on the mechanical connection at this point. Another piece of maintenance is to polish around the “king pin” where the truck swivels, and on any contact surfaces.

Smoke could simply be a sign of too much grease/oil, or it the motor overheating. This could be result of parts being too tight, or be an indicator to other problems. To check if it’s the motor, firstly remove the couplings to run a test on the motor free of any connections. Listen out for any clicking from the drive train. Sometimes a tiny particle of flash can get on a gear. You might need a microscope to see it, but it can settle at the bottom of the valley between the teeth. Use a pick or small file to remove any flash. Another possible cause could be a tiny speck of metallic ballast that has been picked up. Commercial ballast should have no magnetic debris in it, but real dirt could have some iron in it.

Smoke could simply be a sign of too much grease/oil, or it the motor overheating. This could be result of parts being too tight, or be an indicator to other problems. To check if it’s the motor, firstly remove the couplings to run a test on the motor free of any connections. Listen out for any clicking from the drive train. Sometimes a tiny particle of flash can get on a gear. You might need a microscope to see it, but it can settle at the bottom of the valley between the teeth. Use a pick or small file to remove any flash. Another possible cause could be a tiny speck of metallic ballast that has been picked up. Commercial ballast should have no magnetic debris in it, but real dirt could have some iron in it.

If you notice the speed is inconsistent it could be caused by a faulty “u” joint or loose tubing if it was used for coupling to the driveshaft.

Add your comments and share this posting with friends.

Howard asks for advice from others in the hobby:

“On the new HO layout I will probably solder feeder wires to the flex track at the workbench. I don’t want to solder under the layout this time. What color suitcase connectors should I use and what size wires will they use? I’d prefer to use solid copper #12 for the bus wires and 22 solid for the feeders. Who has done this and can tell me about it? Thanks.”

Add your suggestions.

John seeks help from others in the hobby:

“How do you take an HO engine shell off to make repairs. I’ve tried but to no avail and I do not want to break the plastic body.”

Add your comment.

Gil wants your help:

“I have 2 N gauge Rivarossi Pullman cars and a model power freight car that are giving me grief as the wheels will not stay attached to the micro trains chassis. It seems to me that the holes for the wheels have now worn out so that they no longer have the capacity to hold the axles in place. Any clues or do I need to buy wheels/chassis….by the way this is not a constant problem ..it doesn’t occur all the time when trains are running, but it is annoying.”

Add your comment.