Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Using Wooden Doors To Support A Layout

Ricky is planning his first HO layout and seeks guidance from readers:

“Am I on the right track (excuse the pun!)? I plan to use a couple of plain 3ft wide wooden doors as the foundation for my layout, but I am not sure if I am doing the right thing. I’ll use 3/8 inch dowel to join them and use wire harnesses at the joints. I thought this would be better than using plywood as with ply might need bracing diagonally which would make it even heavier. My plan is to apply cork or foam sheets on top to provide the height. Would this work, or is there a better way to do it?”

JUST RELEASED – 40 of the Most Detailed & Realistic Looking Scale Model Containers Ever!

A brand new series of 10ft, 20ft, and 40ft intermodal shipping containers has just been released. The intricate detailing has to be seen to be believed!!! Some a covered in rust, and others have graffiti on one side. There is even a selection of refrigerated containers with motors on one end. The logos designs are unique and are not available anywhere else.

A brand new series of 10ft, 20ft, and 40ft intermodal shipping containers has just been released. The intricate detailing has to be seen to be believed!!! Some a covered in rust, and others have graffiti on one side. There is even a selection of refrigerated containers with motors on one end. The logos designs are unique and are not available anywhere else.

The huge advantage with these model shipping containers is that you are able to scale them to HO, OO, or N scale by simply adjusting the settings on your printer. After downloading them, you can make several copies of each container if you want to, so they work out really cheap if you want to stack them high.

Take a close-up look at this new series of scale model shipping containers here.

More FREE Fun Train Room Signs

The 16 FREE A4 signs I mentioned on the blog last week proved very popular. It sounds like a lot of people have printed them out and put them on a wall near their layout. Others have shared them with friends, so that’s good news!

This week I have a couple more FREE signs for you. They can be printed out, or published on your Facebook Page or website, or emailed to friends. The first one features a drawing of ‘The Dedicated Model Railroader.’ I don’t know whether you can relate to this guy or not. Click here to get the FREE model railroader wall sign.

This week I have a couple more FREE signs for you. They can be printed out, or published on your Facebook Page or website, or emailed to friends. The first one features a drawing of ‘The Dedicated Model Railroader.’ I don’t know whether you can relate to this guy or not. Click here to get the FREE model railroader wall sign.

![]() The second poster is what’s technically called an ‘infographic.’ This is because it is a graphic that includes information. It too is FREE to download and print for the wall, or it can be posted on Facebook, or published on a webpage. The infographic show some interesting railroad facts that will be a talking point for visitors to your layout. Click here to get the FREE infographic.

The second poster is what’s technically called an ‘infographic.’ This is because it is a graphic that includes information. It too is FREE to download and print for the wall, or it can be posted on Facebook, or published on a webpage. The infographic show some interesting railroad facts that will be a talking point for visitors to your layout. Click here to get the FREE infographic.

![]() And finally, a model railroading cartoon that can be printed for your noticeboard, posted on Facebook or on a website (if you have one). Again, it’s intended to be a little bit of fun. You are welcome to share it with friends. Click here to see the cartoon.

And finally, a model railroading cartoon that can be printed for your noticeboard, posted on Facebook or on a website (if you have one). Again, it’s intended to be a little bit of fun. You are welcome to share it with friends. Click here to see the cartoon.

See below for the 16 FREE signs I gave you last week.

16 FREE Train Room Signs

Here’s a bit of fun! Our friends at modelbuildings.org now have 16 novelty signs for your workshop or train room wall. You just download them (there is no charge) and print them out. You can pin or stick them to a wall or perhaps laminate them, or even throw a photo frame around a couple.

Here’s a bit of fun! Our friends at modelbuildings.org now have 16 novelty signs for your workshop or train room wall. You just download them (there is no charge) and print them out. You can pin or stick them to a wall or perhaps laminate them, or even throw a photo frame around a couple.

Although they are copyrighted, you are allowed to share them providing you don’t alter them in any way or try to sell them. These 16 model railroader signs are FREE for you to download here.

BE WARNED: These signs will create a lot of interest and discussion. Your family and friends might not agree with everything they read on these signs, but they’re just meant to be a bit of fun. I don’t think anyone will get upset, but you might take a bit of a ribbing, especially if you remotely resemble the fellow on the left.

Remember to share the link with your friends on Facebook, Twitter, by Email, and Google + etc. The free signs are quickly and easily downloaded in PDF format. ENJOY!!!

Dismantling, Moving, and Reassembling Layout

Colin wants to hear from anyone who has relocated house and layout. He asks:

I made a big mistake not building my 11ft x 8ft HO layout in modules, although part is built on an 8 x 4 base and the rest tacked on.

Now we are moving interstate and I am not sure how to dismantle and move my precious railroad without damaging it. Most of the scenery is made from paper mache. The buildings and two bridges will detach okay. I can dismantle the legs without too much difficulty as they are screwed in place.

But, for the main layout itself, I don’t know where to begin. I don’t want to wreck it pulling it part or damage it in the move. I know I am probably asking the impossible, but I don’t know where to start.

Please help.

Setting Up Tracks and DCC

Ben is new to the hobby and seeks advice from readers:

I have started planning my first layout – a 12 ft x 6 ft HO railroad with a small mining town, at least one industry and some mountains. I think I will cope ok with the scenery side of things, but will struggle with the technical stuff (not my strong point).

Can someone advise me how to begin the DCC setup with transformers and booster (how many would I need)?

Can I mix brands and loco types on the same track? Any other suggestions appreciated.

Electro-Luminescent Wires On Model Railroads?

Julie has a question for experienced model railroaders and asks:

Julie has a question for experienced model railroaders and asks:

“Does anyone have experience with Electro-Luminescent Wire (EL wire) to simulate things like banks of florescent lighting, or shop signs? Do you recommend for or against?”

Add your comment to help.

Easy Tunnel Access

Tunnels can really add interest to a layout with trains disappearing inside a mountain and mysteriously reappearing on the other side. However, there needs to be careful planning to ensure there are no problems inside the tunnel that could potentially cause a train to derail. It is the old “Murphy’s Law” where trains will more than likely derail in the most inaccessible area of the layout. The most hard to get at place is usually inside a tunnel.

Tunnels can really add interest to a layout with trains disappearing inside a mountain and mysteriously reappearing on the other side. However, there needs to be careful planning to ensure there are no problems inside the tunnel that could potentially cause a train to derail. It is the old “Murphy’s Law” where trains will more than likely derail in the most inaccessible area of the layout. The most hard to get at place is usually inside a tunnel.

That’s why considerable thought is required in the event of such a scenario. This needs to happen at the planning stages, before the tunnel is positioned in place.

A couple of options would be to include a removable tunnel section to allow access, or an opening in the base where your hand could reach up to retrieve the cars. An access hole in the side of a mountain can sometimes be disguised by clever positioning of scenic features like trees, grass, shrubbery, rocks etc. It could be as simple as removing a couple of strategically placed rocks that hide the access hole, and then slotting them back in position when the job is done.

A couple of options would be to include a removable tunnel section to allow access, or an opening in the base where your hand could reach up to retrieve the cars. An access hole in the side of a mountain can sometimes be disguised by clever positioning of scenic features like trees, grass, shrubbery, rocks etc. It could be as simple as removing a couple of strategically placed rocks that hide the access hole, and then slotting them back in position when the job is done.

Another option is to add a layer of plastic between the tunnel and the mountain structure, so that the mountain section can be lifted off in one piece, to reveal the tunnel. Then just lift up the tunnel and retrieve the cars or access the track.

If readers have other suggestions, please leave a comment for other to see.

No Train Derailments?

Although it is almost impossible to avoid all derailments, there are ways to limit the likelihood of them happening. This video has makes some excellent points.

The resource mentioned in the video

Only Enough Space for a 10ft x 9ft Railroad

Mark used the “Submit Your Question” link in the right hand column to post this question:

“I only have enough space for a new 10ft x 9ft layout but don’t know whether to switch from HO scale to N scale. I already have some HO gear from my last layout but I had more space for that. With less space I can’t decide if I should make the switch to N scale which would give me more room for the scenery etc. What is best for in my 10 x 9 space? Does anyone have a similar size space?”

Constant Derailments

Warren sent in this question:

“I am in the process of constructing my rural country/mountain layout in HO scale 12ft x 4ft. I’m working on two tunnels right now and am about to lay the track where the tunnels will go. However, I have already had quite a few problems with my cars derailing at the switches so I don’t want to proceed until I can solve the derailments. I have replaced a few wheels on the cars, but the problem still exists. I would really appreciate it if one of your readers could give me some advice. Thanks in anticipation.”

Planning a Mining Town

Steve used the link on this page to submit this question to readers:

“I only started my layout 11 months ago and am planning a mining or old west town… I haven’t yet decided because I haven’t yet done any scenery or structure stuff on my layout. Has anyone got any good ideas for what types of scenery or structures I could incorporate into a small mining town or wild west town? I am open to ideas. Thanks.”

Converting to Automatic Couplers

Richard asks readers:

“I have a whole bunch of older style HO scale cars which I want to change over with automatic couplers. My question is what kind is best and will it be a difficult and time consuming process? Does someone who has done the conversion know?”

Model Train Track Spacings

Tim used the form on this page to submit this question to readers.

“I saw an earlier question about road widths and thought I would ask my question on track widths. What spacing should I use between N track where my two tracks run side by side? What spacing should I use for my curves? The NMRA standards is gobbledygook to me.”

What’s the Maximum Climbing Gradient for Model Trains?

Model trains will usually operate faster on long straight flat stretches of track, but that can be boring after a while, not to mention the amount of space required to run a long mainline. There’s nothing wrong with having flat level areas of track, but changing the elevations by including gradients (slope of railroad track) can add considerable interest to a layout. Adding grades to a model railroad can increase the option of including tunnels, bridges etc as the trains meander through the countryside or mountain ranges.

However, railroad grades need careful consideration if you are to avoid operational problems such as derailments or stalling locomotives. It’s not just the loco that will need to safely navigate up or down the raised track, it is also the fully laden cars carrying coal, timber, metal, refrigerated foods, fuels, vehicles, livestock, or even people (well, plastic models of people). A long train can be very heavy and this needs to be taken into consideration when going up or down a gradient of a real railroad, or on a scaled down model railroad.

Consider Train Weight and Wheel Traction

Let’s look at a real life example: A loaded train might have 135 coal wagons, with each one weighing 22 tons (empty) or 143 tons (loaded with coal). 135 cars x 143 tons equates to 19305 tons with the 3 locomotives moving the train (approx. 630 tons). Add that up and the weight could be up to 20,000 tons (40 million pounds).

Those are staggering figures, and the same rules of physics apply on a model layout.

A model train locomotive will need enough power to safely pull its cars up (or down) a grade without slowing to a stop or a derailment happening. A “gutless” engine won’t haul many cars up a steep grade, so if you want steep grades, you’ll require strong locomotives.

In general, more weight means greater wheel traction. A heavier loco might be able to climb a steep grade, whereas the wheels on a lighter weight loco might slip. Following this logic; a larger scale loco might cope better on steeper grades than would a smaller scale loco.

Multiple Unit Loco Consists

These days it’s often more cost efficient for a railroad to operate longer trains with multiple locomotives. With more pulling (or pushing) power a train can climb a steeper grade and/or have more cars attached. It is not uncommon to see multiple locos on smaller N scale layouts. They are typically at the front of the train, but sometimes there’s a loco positioned in the middle to add more pulling/pushing power.

Using extra locomotives is nothing new. In the days of steam engines the railroads often had “helper” engines standing by to help haul trains up the steeper gradients.

Another method is to use a ‘ghost car’ (sometimes called a cheater car) on your model railroad. This is basically a motorized boxcar or freight car that can be positioned somewhere towards the center of a long train. If the model train is really long, then more than one ‘ghost car’ can be used. They just need to be evenly spaced along the train.

How Steep Should The Track Grade Be?

A track gradient is measured as a percentage of rise over the length of the track. So if the model train track stretches for 100 inches, and over that distance the train climbs by one inch, then the gradient would be 1%. That’s a comfortable gradient for most model trains to navigate. Compare that to a short 25 inches of model train track with the same 1 inch rise – that would be really steep and equate to a 4% rise. A steep 4 percent rise could be problematic and likely cause a lot of frustration.

Track grades on real railroads fall into there categories; light grade is 0.8% – 1%, heavy grade 1% – 1.8%, and above 1.8% is classified as mountain grade. Real railroads need to make money, so having trains stall or derail can prove costly.

Broken down trains can block the line (upsetting schedules), derailed trains can be expensive to get back on the tracks, damaged goods (or passengers) is bad for business, and damaged trains or track can run into big money to replace or repair. That’s why real railroads choose to minimize operating costs and minimize risks, by avoiding overly steep gradients. They avoid anything that could have an adverse effect on operations.

The same goes for model railroads; keeping track gradients 2% or below is a good rule of thumb. It can also look more realistic (as long as you have the space) than a really steep grade. As I mentioned earlier, a 1 percent grade poses few problems on most layouts.

As with life-size railroads, the grades on a model railroad will be determined by the weight and length of trains. Other factors will be the number (and type) of locos being operated and the track speed limit. That’s not to say model trains can’t or don’t operate on grades of 4%, 5%, or even 6% – they do. But the steeper grades are more likely to operate short trains, geared locos, and at slow speeds. A good example might be a train hauling logs or coal from a mountain region. So, grades of 4% or higher are manageable on some layouts.

How Track Length and Grades Impact Operations

Helper locos are often used when trains need to haul heavy loads especially above grades of 1.5%. Mainline grades are generally below 2%.

The thing to remember is that on real railroads the trains gain considerable momentum on long straight level sections of track. If the track runs level for several miles and then has a small ½ mile run of steeper 2 percent grade, then the power of the train will take it up the grade without too much effort. So, from a railroad management view point, the 2% grade is unlikely to disrupt schedules or add greatly to the running costs. The same can’t be said for a 1.5% to 2% grade that stretches several miles. A lot more pulling power would be required to haul the same train.

More info on model train grades, realistic scale speeds

Curves and bends also influence operations on level ground as well as on gradients. An easement for a curve needs to be gradual, as does the transition into a gradient. A sudden change to track slope or angle is a recipe for disaster, posing a higher risk of unplanned uncoupling or even derailments. Special care needs to be taken when constructing curves within a gradient. This is because curves increase the wheel and rail friction making it more difficult to haul a train up a curving gradient, and less troublesome taking it down.

However, a including curves on grades can give a longer run where space is limited on a model railroad. This can reduce the grade percentage needed. Gradients can add considerable interest to a scale railroad, especially where one track passes over another on trestles or bridges. However height is needed for an over/under configuration, so there needs to be sufficient space for the train to climb and turn.

Including grades is good; including curves is good; but the mix of curves and grades needs to right. Too many, or overly tight, curves can cause problems. The same goes for ‘S’ curves – care needs to be taken when planning the configuration. As long as there are no track or wheel faults, a train will generally run along a straight section of track without difficulties. Add a tight curve, an ‘S’ bend, or steep gradient, and train speed and operation changes.

Curves and Grades Need Space

To achieve continuous running, a layout will need 180 degree curves so the train can turn around without stopping. Due to space limitations, this is not possible on every layout, especially on narrow railroads. The minimum radius of curves will also vary depending on the scale.

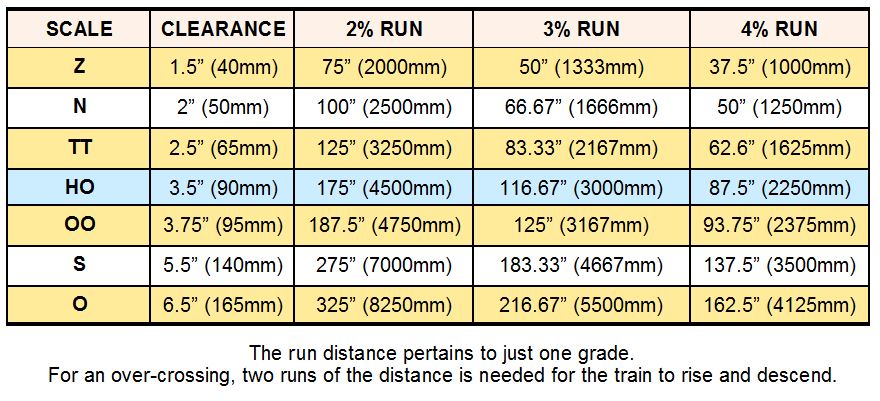

The above chart shows various scale clearances needed when planning tunnels and bridges. Remember that when a track rises it generally needs to come back down again, so the length of the grade will need to be doubled to allow for both the rise and descent.

When constructing a layout it is always best to try and avoid potential problems, rather than try to fix problems after they have happened. Simply things can save a lot of frustration, like testing the trains on your layout BEFORE gluing down the track and grade foam. The trains need to comfortably navigate the track without mishaps. They need to be able to take the curves without derailing and climb the grades without coming to a standstill. Obviously you will need to decide how many cars each train is likely to have to conclude whether the track configuration is adequate for your needs. There’s no point in having a fancy layout that isn’t practical to operate.

DCC Fitted Engine Won’t Run on DC?

Colin asks readers:

“I’ve purchased an HO loco fitted with a DCC chip, and it operates great on DCC, however I can’t get it to move on DC. How can I

fix this?

If you want to submit a question to the Blog Moderator for possible publication, please use the link in the right hand column of this bog.