Everything on model trains, model railroads, model railways, locomotives, model train layouts, scenery, wiring, DCC and more. Enjoy the world's best hobby... model railroading!

Coming Soon…

In a few days the folk at www.modelbuildings.org will be releasing a new series of 6 Wild West scale buildings to download. I’ve seen the Sheriff’s Office and General Store assembled and the detailing is exceptional. The clever twist is that they will be supplying extra signage so that various buildings can be easily altered. So the signage on the General Store could be changed to read “Boot & Shoe Repairs”, or possibly “Draper.” So with a little extra effort and no extra cost, the Wild West Town could become a 1930’s country town. Clever!

Also, in a few weeks they hope to be ready to release a series of model mining buildings to download. I’ll let you know when they’re available.

DCC Engine Runs In Reverse?

Les asks readers:

“My DCC engine only runs in reverse. I bought a used Lifeline Proto 2000 Series SD60M engine with DCC (no sound). I use an MRC Tech 6 Sound Controller 2.0 power pack. The engine checked out fine on the store’s test track and I have had no problem with the MRC on both my DC and DCC Sound engines. But the SD60 will only run in reverse and only in the Standard Mode. It does not move, light up, etc. in DCC Mode. There is no manual for the SD60, and I have no real skill with programming DCC. Can someone help with getting the engine to run as it should? Thank you very much.”

Single Cab Running

Shaun has a question for readers and asks:

Shaun has a question for readers and asks:

“I need someway of hiding the left hand track – the other two are for a station.

And the diagonal track crosses the polarity when it reaches the station tracks.

Is there an easy wiring method to correct this to allow single cab running?”

Add your suggestions to help Shaun

Using LED Lights For Model Passenger Trains

Club member Trevor asks readers for advice with his LED lights:

“Recently I installed lighting inside a couple of passenger train cars using the new led strip system. It worked perfectly until the train started to move and then the LED’s started to flicker which ruined the effect. I have a DCC system, and my track is clean. I have new wheels and pickups so I’m not sure what the problem is. I would appreciate any guidance from others who have experience using LED’s on their trains. Thanks in advance.”

Please add your comment if you think you can help Trevor.

You can join the model train club here.

Another FREE Novelty Wall Poster To Liven Up Your Train Room or Model Railroad Clubhouse

Thanks for all the amazing feedback from those who downloaded the 16 free wall posters I gave you a few weeks back. I’m glad you enjoyed them!

This week I have another fun A4 wall poster you can download and share for free. It is totally free – there are no catches – you don’t need to enter a name and email address or anything like that. You can even email it to friends or post it on your Facebook or Google Plus page if you have one. It is just a bit of fun, so I hope you enjoy it. You can download load it here for free as a PDF file.

This week I have another fun A4 wall poster you can download and share for free. It is totally free – there are no catches – you don’t need to enter a name and email address or anything like that. You can even email it to friends or post it on your Facebook or Google Plus page if you have one. It is just a bit of fun, so I hope you enjoy it. You can download load it here for free as a PDF file.

If you missed the other 16 FREE railroad posters you can download them free here.

At the bottom of the same page is a link to a couple of free railroading infographics and a model train cartoon. These may be of interest to any of you who have websites, as they can be published for free.

These signs are all courtesy of the folk at modelbuildings.org, so please support them if you can.

A Fascinating Glimpse at Train Travel In India, Pakistan and China

People in developed countries certainly enjoy the benefits of generally fast and efficient train travel, but in some countries the trains are very crowded and the infrastructure is older and slower. This quick video shows some interesting scenes and comparisons. Feel free to share it with your friends.

Track Conditioning

Lee has a question for readers:

“I live on the coast of NC. My O scale layout goes from the game room through the wall into the garage.

The ‘Salty’ air is rusting the track. I use steel wool, sand paper, and everything else I can think of. Is there ANY treatment that can be done to help?”

If you would like to post a question, please follow the guidelines in the right hand column.

Add a Rusty Junkyard to your Trackside Scene

Ron B sent in this article to share:

Ron B sent in this article to share:

The world is far from perfect especially when it comes to everyday scenes. It is not uncommon to see trash, litter, and junk lying around streets or in fields. That’s why adding trash to a model railroad scene can add realism and bring a scene to life.

And, it can be a lot of fun making the items for a junkyard scene. It could include damaged or abandoned vehicles, a rusty old shipping container, perhaps lots of spare parts and oil drums scattered around, and maybe a dilapidated broken down old fence of some kind surrounding the yard. The yard will most likely be overgrown with weeds or vegetation, so that will be another way to add realism.

The good thing is; you don’t necessarily need to use expensive model vehicles for this type of project, because you’ll probably want to cut them apart, repaint and weather them. Junk car sets are available from companies like Walthers as well as piles of ready-made junk, piles of tires and scrap metal bales. However that said; I personally prefer to make my own and enjoy doing so.

If you are including abandoned automobiles, remember to choose models that are older than the setting of your scene. After all, it is likely they have been abandoned for some time, especially if they are covered in rust. When it comes to adding the rust effects, I use powdered pastels in various colors, although you can use an airbrush to apply rust colored model paints.

The powdered paints have tiny particles of pigments that get into the gaps and the effect can be altered depending on what color combinations you use and how much you apply. I finish off with a really thin film of rust-colored powder, but take care not to apply it too thickly as you’ll want the darker deep-seated old rust areas to still be seen. The lighter shades will usually indicate patches of newer rust. I sometimes mix very fine sand with the powders to give a rougher rusty surface in some places.

The powdered paints have tiny particles of pigments that get into the gaps and the effect can be altered depending on what color combinations you use and how much you apply. I finish off with a really thin film of rust-colored powder, but take care not to apply it too thickly as you’ll want the darker deep-seated old rust areas to still be seen. The lighter shades will usually indicate patches of newer rust. I sometimes mix very fine sand with the powders to give a rougher rusty surface in some places.

I use some long nosed pliers or tweezers to hold the model in place so I can dismantle or cut a vehicle into sections. I use a motor tool with a fine tooth saw to remove doors, hoods, and/or fenders. I usually remove the parts before painting them to ensure the cut edges match. When I glue them back in place with Super Glue (cyanoacrylate adhesive), the joins usually look quite rough which adds to the effect. I also scratch the surfaces of the bodywork with a craft knife which can look like the paint is damaged. Dents and scrapes add extra realism.

Care is needed when positioning vehicles in the junk yard. It’s unlikely they would have been lifted in by a crane, so they could be positioned at odd angles. There will probably be old auto parts, axles, doors and wheels leaning against the bodywork. Grass and weeds may be spouting through some of the windows and around the wheels. The scene can be completed with a couple of people or a dog in the yard. Use your imagination, because the possibilities are endless.

Using Wooden Doors To Support A Layout

Ricky is planning his first HO layout and seeks guidance from readers:

“Am I on the right track (excuse the pun!)? I plan to use a couple of plain 3ft wide wooden doors as the foundation for my layout, but I am not sure if I am doing the right thing. I’ll use 3/8 inch dowel to join them and use wire harnesses at the joints. I thought this would be better than using plywood as with ply might need bracing diagonally which would make it even heavier. My plan is to apply cork or foam sheets on top to provide the height. Would this work, or is there a better way to do it?”

JUST RELEASED – 40 of the Most Detailed & Realistic Looking Scale Model Containers Ever!

A brand new series of 10ft, 20ft, and 40ft intermodal shipping containers has just been released. The intricate detailing has to be seen to be believed!!! Some a covered in rust, and others have graffiti on one side. There is even a selection of refrigerated containers with motors on one end. The logos designs are unique and are not available anywhere else.

A brand new series of 10ft, 20ft, and 40ft intermodal shipping containers has just been released. The intricate detailing has to be seen to be believed!!! Some a covered in rust, and others have graffiti on one side. There is even a selection of refrigerated containers with motors on one end. The logos designs are unique and are not available anywhere else.

The huge advantage with these model shipping containers is that you are able to scale them to HO, OO, or N scale by simply adjusting the settings on your printer. After downloading them, you can make several copies of each container if you want to, so they work out really cheap if you want to stack them high.

Take a close-up look at this new series of scale model shipping containers here.

More FREE Fun Train Room Signs

The 16 FREE A4 signs I mentioned on the blog last week proved very popular. It sounds like a lot of people have printed them out and put them on a wall near their layout. Others have shared them with friends, so that’s good news!

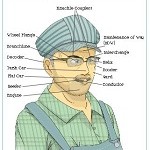

This week I have a couple more FREE signs for you. They can be printed out, or published on your Facebook Page or website, or emailed to friends. The first one features a drawing of ‘The Dedicated Model Railroader.’ I don’t know whether you can relate to this guy or not. Click here to get the FREE model railroader wall sign.

This week I have a couple more FREE signs for you. They can be printed out, or published on your Facebook Page or website, or emailed to friends. The first one features a drawing of ‘The Dedicated Model Railroader.’ I don’t know whether you can relate to this guy or not. Click here to get the FREE model railroader wall sign.

![]() The second poster is what’s technically called an ‘infographic.’ This is because it is a graphic that includes information. It too is FREE to download and print for the wall, or it can be posted on Facebook, or published on a webpage. The infographic show some interesting railroad facts that will be a talking point for visitors to your layout. Click here to get the FREE infographic.

The second poster is what’s technically called an ‘infographic.’ This is because it is a graphic that includes information. It too is FREE to download and print for the wall, or it can be posted on Facebook, or published on a webpage. The infographic show some interesting railroad facts that will be a talking point for visitors to your layout. Click here to get the FREE infographic.

![]() And finally, a model railroading cartoon that can be printed for your noticeboard, posted on Facebook or on a website (if you have one). Again, it’s intended to be a little bit of fun. You are welcome to share it with friends. Click here to see the cartoon.

And finally, a model railroading cartoon that can be printed for your noticeboard, posted on Facebook or on a website (if you have one). Again, it’s intended to be a little bit of fun. You are welcome to share it with friends. Click here to see the cartoon.

See below for the 16 FREE signs I gave you last week.

16 FREE Train Room Signs

Here’s a bit of fun! Our friends at modelbuildings.org now have 16 novelty signs for your workshop or train room wall. You just download them (there is no charge) and print them out. You can pin or stick them to a wall or perhaps laminate them, or even throw a photo frame around a couple.

Here’s a bit of fun! Our friends at modelbuildings.org now have 16 novelty signs for your workshop or train room wall. You just download them (there is no charge) and print them out. You can pin or stick them to a wall or perhaps laminate them, or even throw a photo frame around a couple.

Although they are copyrighted, you are allowed to share them providing you don’t alter them in any way or try to sell them. These 16 model railroader signs are FREE for you to download here.

BE WARNED: These signs will create a lot of interest and discussion. Your family and friends might not agree with everything they read on these signs, but they’re just meant to be a bit of fun. I don’t think anyone will get upset, but you might take a bit of a ribbing, especially if you remotely resemble the fellow on the left.

Remember to share the link with your friends on Facebook, Twitter, by Email, and Google + etc. The free signs are quickly and easily downloaded in PDF format. ENJOY!!!

Dismantling, Moving, and Reassembling Layout

Colin wants to hear from anyone who has relocated house and layout. He asks:

I made a big mistake not building my 11ft x 8ft HO layout in modules, although part is built on an 8 x 4 base and the rest tacked on.

Now we are moving interstate and I am not sure how to dismantle and move my precious railroad without damaging it. Most of the scenery is made from paper mache. The buildings and two bridges will detach okay. I can dismantle the legs without too much difficulty as they are screwed in place.

But, for the main layout itself, I don’t know where to begin. I don’t want to wreck it pulling it part or damage it in the move. I know I am probably asking the impossible, but I don’t know where to start.

Please help.

Setting Up Tracks and DCC

Ben is new to the hobby and seeks advice from readers:

I have started planning my first layout – a 12 ft x 6 ft HO railroad with a small mining town, at least one industry and some mountains. I think I will cope ok with the scenery side of things, but will struggle with the technical stuff (not my strong point).

Can someone advise me how to begin the DCC setup with transformers and booster (how many would I need)?

Can I mix brands and loco types on the same track? Any other suggestions appreciated.

Electro-Luminescent Wires On Model Railroads?

Julie has a question for experienced model railroaders and asks:

Julie has a question for experienced model railroaders and asks:

“Does anyone have experience with Electro-Luminescent Wire (EL wire) to simulate things like banks of florescent lighting, or shop signs? Do you recommend for or against?”

Add your comment to help.

Easy Tunnel Access

Tunnels can really add interest to a layout with trains disappearing inside a mountain and mysteriously reappearing on the other side. However, there needs to be careful planning to ensure there are no problems inside the tunnel that could potentially cause a train to derail. It is the old “Murphy’s Law” where trains will more than likely derail in the most inaccessible area of the layout. The most hard to get at place is usually inside a tunnel.

Tunnels can really add interest to a layout with trains disappearing inside a mountain and mysteriously reappearing on the other side. However, there needs to be careful planning to ensure there are no problems inside the tunnel that could potentially cause a train to derail. It is the old “Murphy’s Law” where trains will more than likely derail in the most inaccessible area of the layout. The most hard to get at place is usually inside a tunnel.

That’s why considerable thought is required in the event of such a scenario. This needs to happen at the planning stages, before the tunnel is positioned in place.

A couple of options would be to include a removable tunnel section to allow access, or an opening in the base where your hand could reach up to retrieve the cars. An access hole in the side of a mountain can sometimes be disguised by clever positioning of scenic features like trees, grass, shrubbery, rocks etc. It could be as simple as removing a couple of strategically placed rocks that hide the access hole, and then slotting them back in position when the job is done.

A couple of options would be to include a removable tunnel section to allow access, or an opening in the base where your hand could reach up to retrieve the cars. An access hole in the side of a mountain can sometimes be disguised by clever positioning of scenic features like trees, grass, shrubbery, rocks etc. It could be as simple as removing a couple of strategically placed rocks that hide the access hole, and then slotting them back in position when the job is done.

Another option is to add a layer of plastic between the tunnel and the mountain structure, so that the mountain section can be lifted off in one piece, to reveal the tunnel. Then just lift up the tunnel and retrieve the cars or access the track.

If readers have other suggestions, please leave a comment for other to see.

No Train Derailments?

Although it is almost impossible to avoid all derailments, there are ways to limit the likelihood of them happening. This video has makes some excellent points.

The resource mentioned in the video

Only Enough Space for a 10ft x 9ft Railroad

Mark used the “Submit Your Question” link in the right hand column to post this question:

“I only have enough space for a new 10ft x 9ft layout but don’t know whether to switch from HO scale to N scale. I already have some HO gear from my last layout but I had more space for that. With less space I can’t decide if I should make the switch to N scale which would give me more room for the scenery etc. What is best for in my 10 x 9 space? Does anyone have a similar size space?”